Skip to content

Neutral Expertise and R&D Review of Production and Operations

- OEM equipment performance analysis to maximize materials processing

- Furnace survey with thermal profiling

- Vibration and acoustic field diagnostics (add-on)

- In-field chemical measurements of castings and in-process materials

- Thermography (infra-red analysis)

Casting Process Optimization

- Solidification modeling to reduce casting imperfections/defects

- Mold and gating system design improvements

- Cycle time reduction and yield maximization

- Chemical distribution predictions and measurements

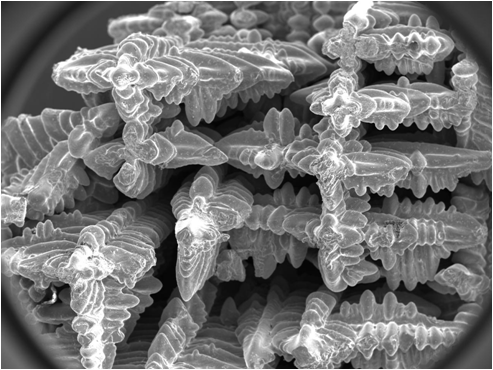

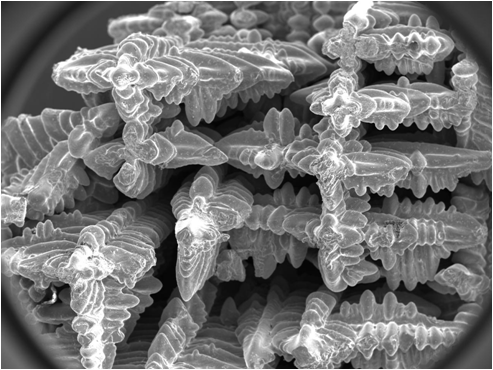

Alloy Development & Tailoring

- Custom alloy formulations for castability, performance, and cost

- Design of high-strength, wear-, and corrosion-resistant cast metals

- Sustainable alloy solutions to reduce critical elements, machining time, and cost

Defect Analysis & Troubleshooting

- Root cause investigation using proprietary field-proven algorithm

- In-field and lab metallographic evaluation and process diagnostics

- Recommendations for material and process corrections

Simulation & Modeling Services

- CAE tools for casting, heat transfer, and stress analysis

- Virtual prototyping to reduce floor trial-and-error

- Prediction of microstructure evolution and properties

Melt Practice & Refining Support

- Best practices for melting, inoculation, and alloying

- Control of impurities, inclusions, and gas content

- Furnace and crucible condition analysis

- Scrap analysis and purification guidance

Thermal Processing & Heat Treatment

- Design and validation of heat treatment cycles for castings

- Phase transformation control and hardening strategies

- Minimization of distortion and residual stress

- Solid-state evolution during processing

Sand System & Mold Material Evaluation (Add-on)

- Analysis and optimization of sand, binders, and additives

- Recommendations for core/mold selection and reuse

- Solutions for burn-on, veining, and erosion

Quality & Process Control Development

- In-process controls: thermal analysis, spectrometry, acoustics, vibration

- Statistical process control (SPC) and LEAN methods

- Traceability and data-driven quality systems

Sustainability & Waste Reduction (Add-on)

- Yield improvement via scrap reduction and process efficiency

- Reuse of return sand and by-products

- Support for environmental compliance and emission control

Training & Technical Coaching

- Hands-on or virtual foundry workshops

- Custom training in metallurgy, defects, process, and Industry 4.0

- Certification and technical development support